To begin with, GD&T symbols are standardized and defined in the ASME Y14.5 criterion, which implies they have global acceptance in engineering self-controls. Flatness, stood for by a two-dimensional sign, guarantees that a surface area is uniformly level within defined restrictions, which is crucial for surface areas that require to mate or seal.

Discover GD&T symbols and guidelines the relevance of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances interaction, accuracy, and cost-efficiency while reducing mistakes via standardized symbols and guidelines.

In addition to create controls, GD&T additionally consists of positioning controls, such as similarity, angularity, and perpendicularity. Comprehending just how to define and analyze these orientation symbols is crucial for accurate manufacturing and quality design.

Area regulates such as balance, concentricity, and placement are additionally important elements of GD&T. Finding out to use these area symbols effectively will aid engineers in accomplishing useful components that fulfill layout specifications while also simplifying the manufacturing procedures included.

An additional essential aspect of GD&T is the concept of datums, which are reference points or surfaces that act as a basis for dimension. The reliable use information is basic in ensuring consistent production high quality. Each datum is designated a letter classification, and it supports the component to sector requirements, making sure that dimensions are repeatable and reliable. Properly defined datums enable engineers to control variations better, reducing the chance of errors in production. These recommendations assist in establishing a robust coordinate system that all tolerances can relate back to, making it important for any design engineer to have a strong grip of just how to use and build datum references.

The usage of GD&T in engineering drawings promotes more clear interaction among stakeholders. When a designer defines resistances utilizing GD&T symbols, it minimizes the uncertainty frequently associated with typical dimensioning techniques. This clarity help makers in recognizing the part requirements properly, consequently increasing the chance of creating parts that fulfill specs on the first effort. In markets where precision and top quality are vital, such as aerospace or medical tool production, the role of GD&T in simplifying interaction can not be overstated. It links the space between layout intent and manufacturing capability, making certain that both celebrations are on the very same page regarding assumptions.

Furthermore, the application of GD&T is valuable for cost performance in manufacturing. Engineers that master GD&T can dramatically influence the cost-effectiveness of their styles without giving up quality or performance.

Numerous academic sources, workshops, and training programs are currently available to assist designers and developers learn the nuances of GD&T. Practical applications of GD&T in situation researches can give understanding into how correctly carried out symbols lead to enhanced top quality and reduced scrap rates in manufacturing.

When modifying or translating engineering drawings that utilize GD&T, attention to detail is paramount. Standardization advertises a society of high quality and uniformity, strengthening the significance of GD&T principles in everyday design technique.

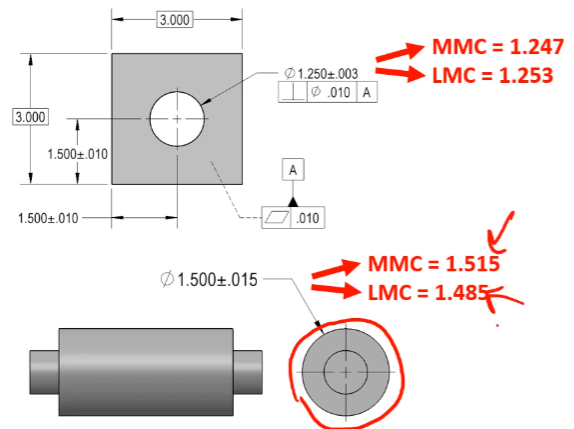

Discover mmb vs mmc the value of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances interaction, accuracy, and cost-efficiency while lessening errors through standardized symbols and guidelines.

In verdict, grasping GD&T symbols and guidelines is an important ability for modern-day engineers, particularly those entailed in style and manufacturing. By spending in proper training and exercising the efficient application of GD&T principles, designers can take advantage of this powerful device to drive development and quality in their styles, ultimately leading to an extra competitive and effective item development lifecycle.